Overview

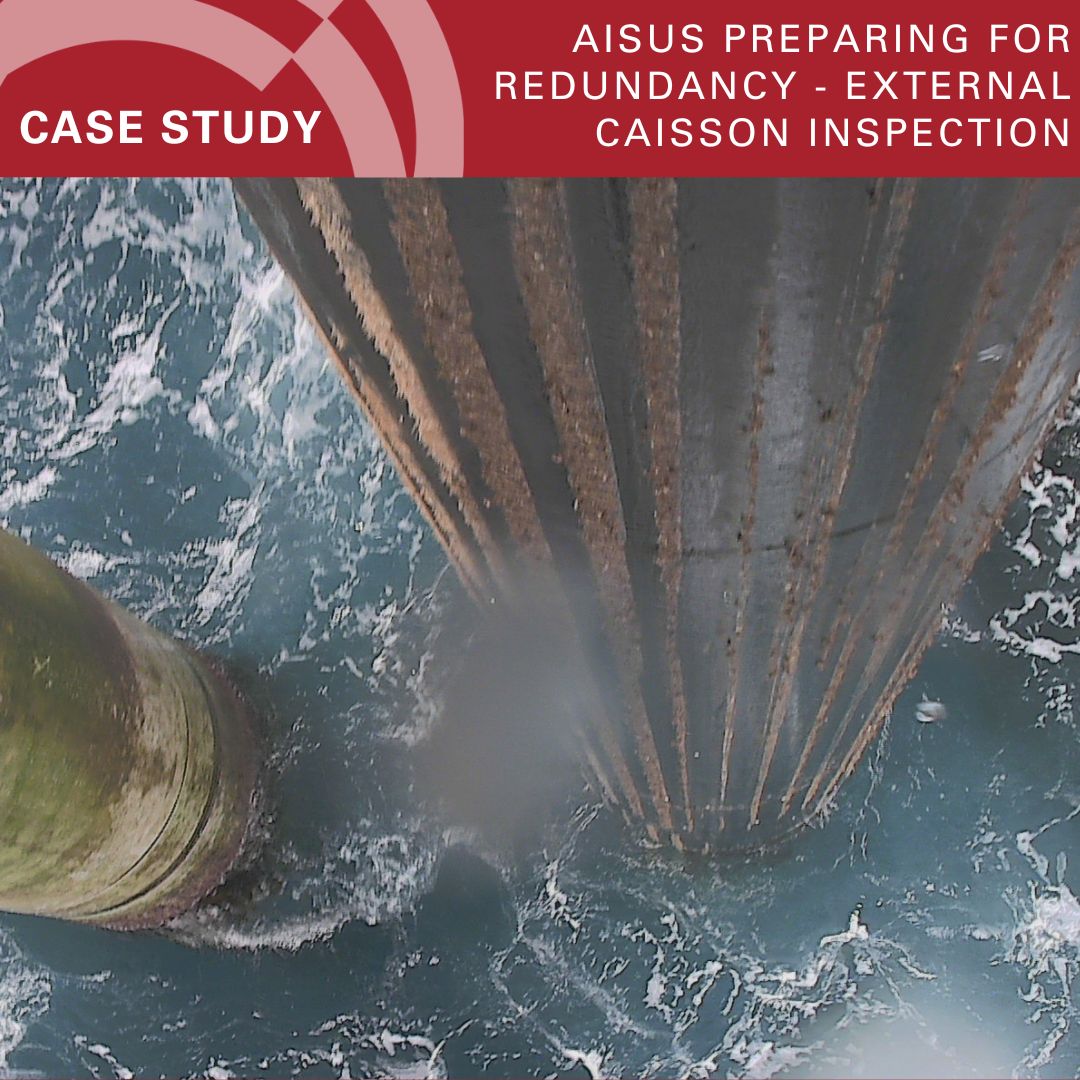

AISUS were contracted to perform a full inspection of four sea water lift caissons on an offshore platform. Collecting UT data from topside to the termination grille and through the splashzone, to ensure structural integrity. The use of advanced remote inspection technologies, including the AISUS ‘SIRIUS’ ultrasonic scanner, enabled a detailed evaluation of the caisson’s condition.

The Requirement

This inspection required HP jetting operations between the top of Caisson as far as the termination to remove marine growth, scale and corrosion product build up from the caisson sidewall to provide an adequate surface to obtain Ultrasonic Test (UT) readings and allow a detailed Remote Visual Inspection of the caissons.

Reporting which details any major anomalies was compiled prior to personnel demobilising, including images, elevations and dimensions of any internal anomalies

The Challenge

- Significant buildup of marine growth on the sidewalls was present, which needed removed to enable clear UT readings

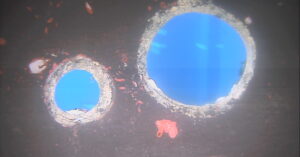

- Caisson terminations were found to be blocked with marine growth

The Solution

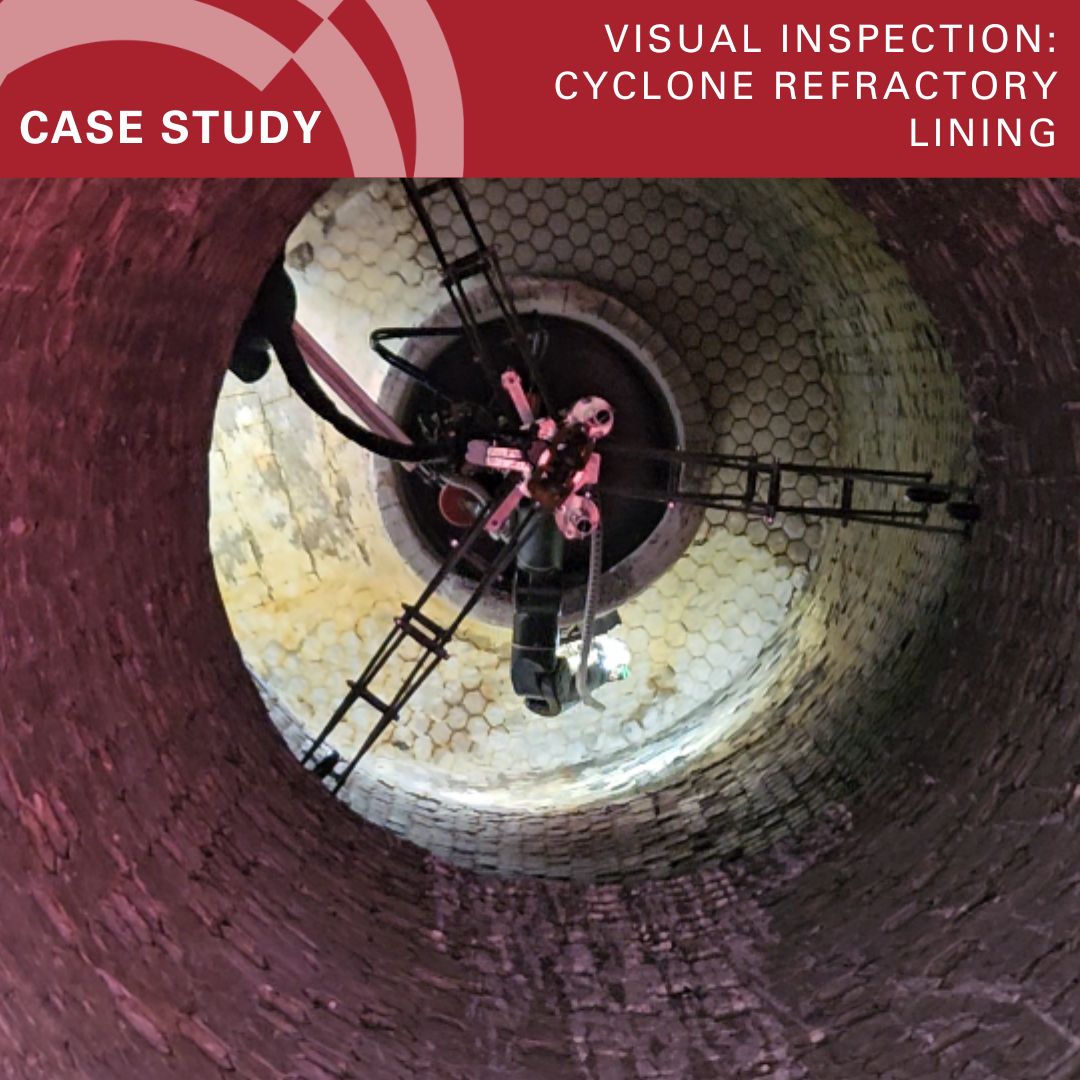

AISUS deployed a series of strategic steps to ensure the success of the inspection. Including a Preliminary Visual Inspection to assess cleanliness and identify the amount of debris, foreign objects, or buildup inside the caisson.

With this information AISUS were able to adjust the HP jetting pressure to ensure adequate cleaning and minimise any potential damage to coating or parent material.

Using a different cleaning head on the tool enabled unblocking and clearing of the grilles

The HP cleaning enabled the AISUS ‘SIRIUS’ ultrasonic scanner to collect wall thickness data across the full length of the caisson

Results

AISUS’ solution provided a comprehensive inspection of the caissons offering detailed insights into their current condition.

High-pressure jetting effectively removed marine growth and debris, leaving a clear pathway from the grilles to the sea. This also enabled a clear visual inspection and more accurate ultrasonic readings.

Over 250 wall defects were found between the caissons and sporadic pitting was highlighted throughout the entirety of the caissons

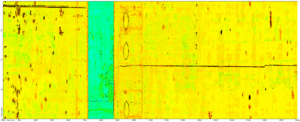

The data presented as C-scans, provided a clear visual representation of the caisson’s internal condition, enabling informed decision-making.

Benefits

- Reduced Personnel Needs: A small three-person team was required, minimising risk and optimising efficiency.

- Accurate Data Collection: The combination of HP cleaning, UT and video visual inspection provided a thorough and reliable dataset.

- Expert Team & Innovative Technology: We deliver reliable and precise results while ensuring high standards of quality and safety

- Streamlined Reporting: access to comprehensive reports of inspection data.