Background

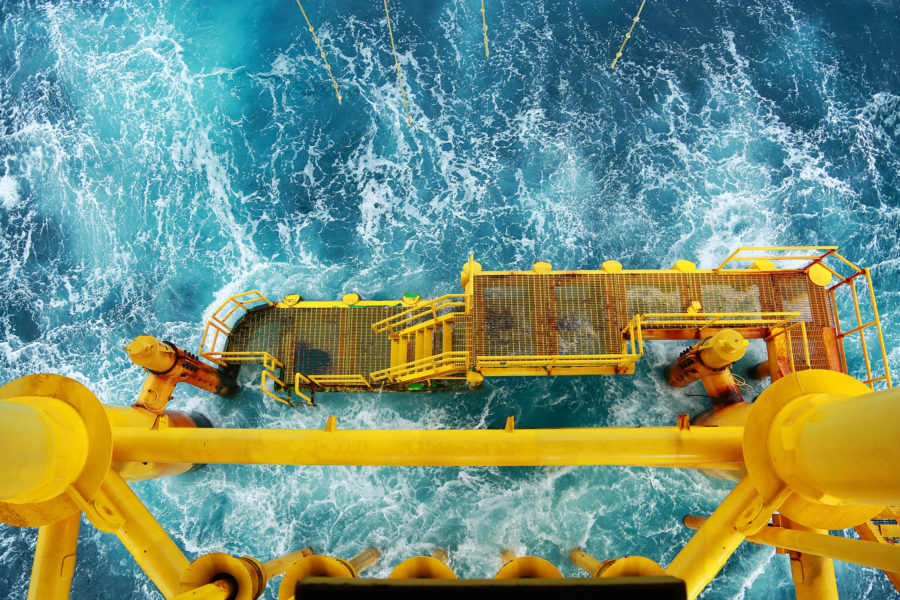

AISUS was tasked by a client in the Norwegian North Sea to carry out a Remote Ultrasonic Inspection on a caisson which had severed.

Experienced and competent engineers were deployed to complete an internal ultrasonic inspection on a seawater lift caisson.

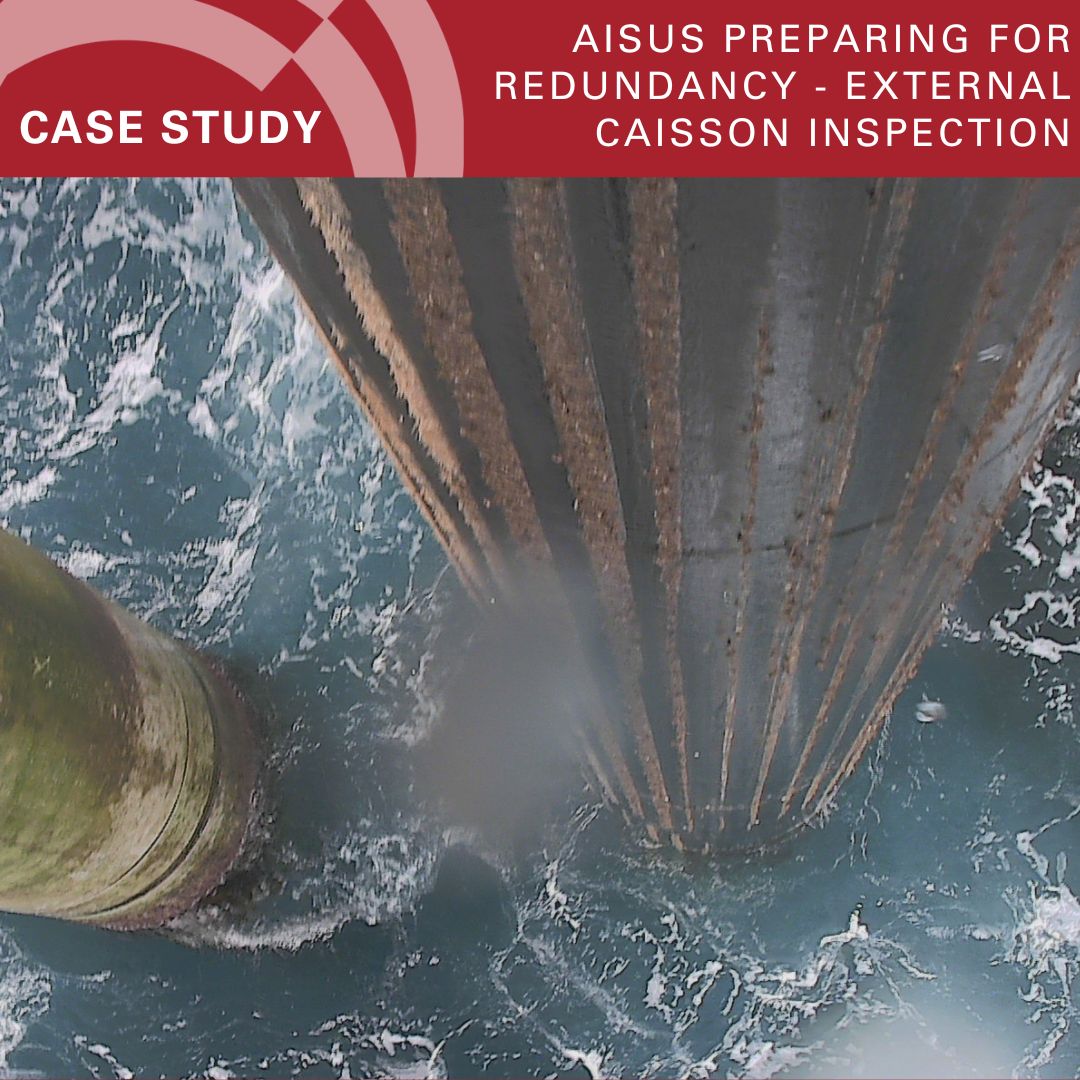

The client’s asset had failed and a section of the caisson had detached at a weld within an external guide support and fallen to the seabed. The remaining length was insufficient to cover the length of the pump string, with pump exposed below. Adoption of external ROV and crawler inspection methods previously had not identified the degradation mechanism which caused the failure. Through regular internal inspection this failure could have been prevented, by identifying the failure mechanism early inside the guide support and allowing the client to put suitable mitigation in place.

The Inspection

On a typical caisson scope of work, AISUS would normally complete the visual inspection along with high pressure cleaning prior to ultrasonic inspection. On this occasion, the operator completed these services with another vendor prior to our arrival. In order to avoid any loss of key information in the inspection process, the visual inspection results were requested prior to AISUS mobilising to the platform.

Followed by the cleaning and visual inspection, AISUS was tasked to carry out an internal ultrasonic inspection to collect the wall thickness data by deploying SIRIUS, an in-house designed and manufactured ultrasonic inspection tool. The scope was required to highlight any other sections of the caisson that were showing signs of deterioration which may have required further attention during a planned repair project.

Benefits

This inspection helped the client to understand the condition of the remaining caisson in order to bring the caisson back into service through the installation of a swaged repair. Internal inspection also identified defects caused by the interaction between the caisson and pump string which would have not been identified using other inspection methods. Identification of these defects allowed the repair scope to be adjusted, extending the length of the swage repair, and ensured unnecessary future risks and costs were mitigated.

The client was delighted with the results of the inspection which gave them comprehensive data on the condition of the remaining caisson prior to the installation of a swaged repair.