INNOVATIVE INTERNAL INSPECTION

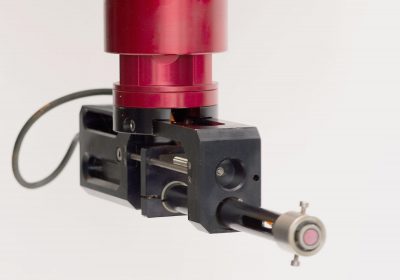

Our compact tool design enables fast and easy to set up, eliminating large, complicated tool packages, that are difficult to transport and operate. Saving costs and time with innovative integrated inspection of your drilling riser system. This is achieved by the elimination of complex removal of the buoyancy, coatings and disassembly of the riser.

A unique set of benefits unavailable from any other inspection source completely changing the way marine drilling riser inspections and certifications are performed.

-

-

- Schedule based inspections – between well, annual, five and ten yearly

- Automated main tube and auxiliary line inspection

- Automated circumference scanning

- Flange to pipe and pipe to pipe welds, TOFD & PAUT inspections

- Riser & BOP bolt inspection – in situ no need to remove

- Complies with industry-standard codes and recommended practices

- Condition Based Maintenance programme “CBM”

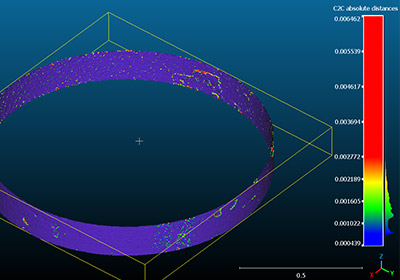

- Data management supporting CBM with accurate data storage and comparison

- Survey onshore or offshore

- Horizontally stacked inspections – reduced lifts

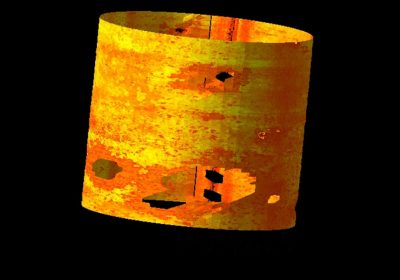

- Improved Inspection using advanced techniques

- A more comprehensive inspection with greater accuracy of results

- Digitally recorded results and images for future comparison

- Greater repeatability for trending

- Graphic displays for easier interpretation

- HP & UHP Cleaning

-

CASE STUDY