Integrating Robotics with Aurgia for Enhanced Inspection in Hard-to-Reach Areas

Overview

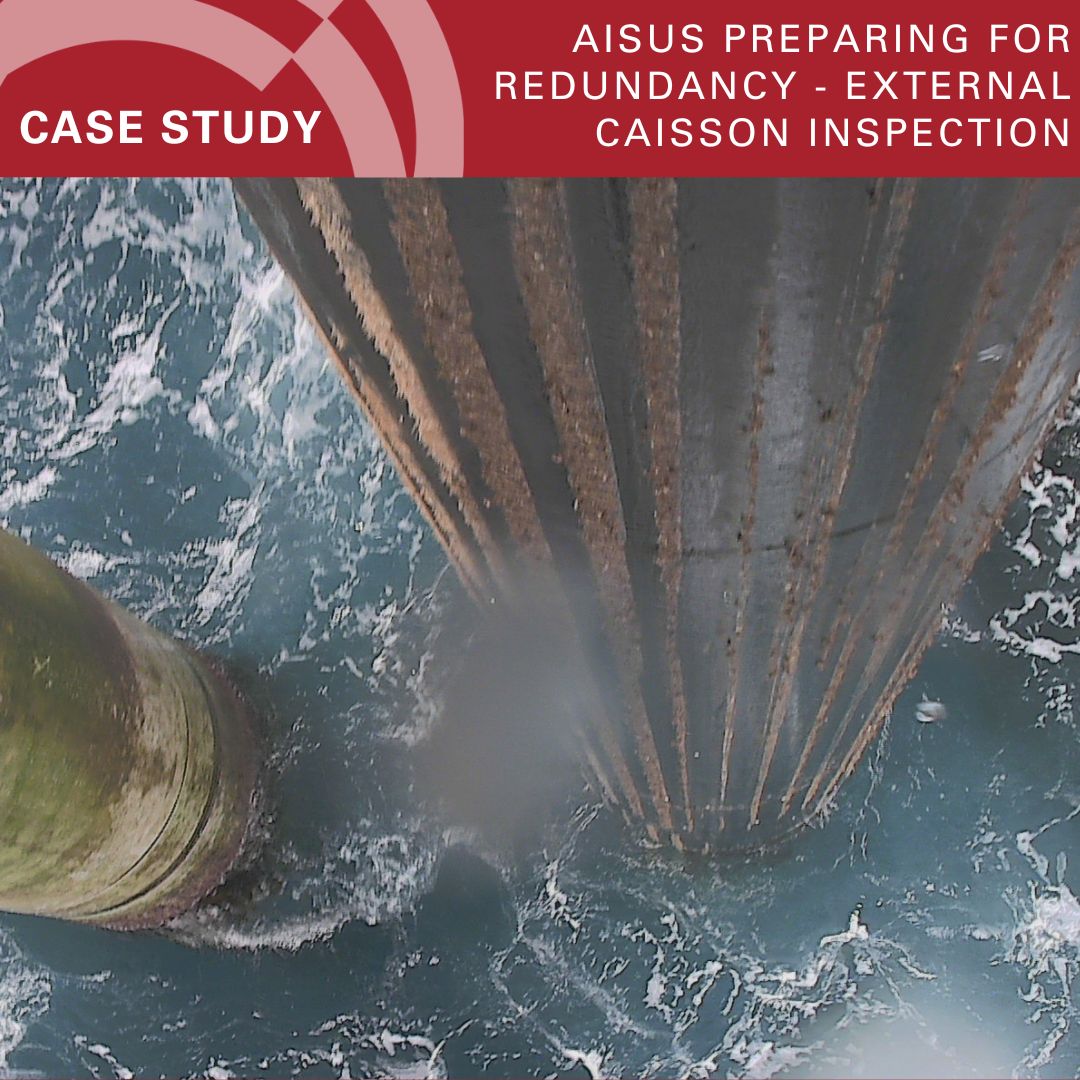

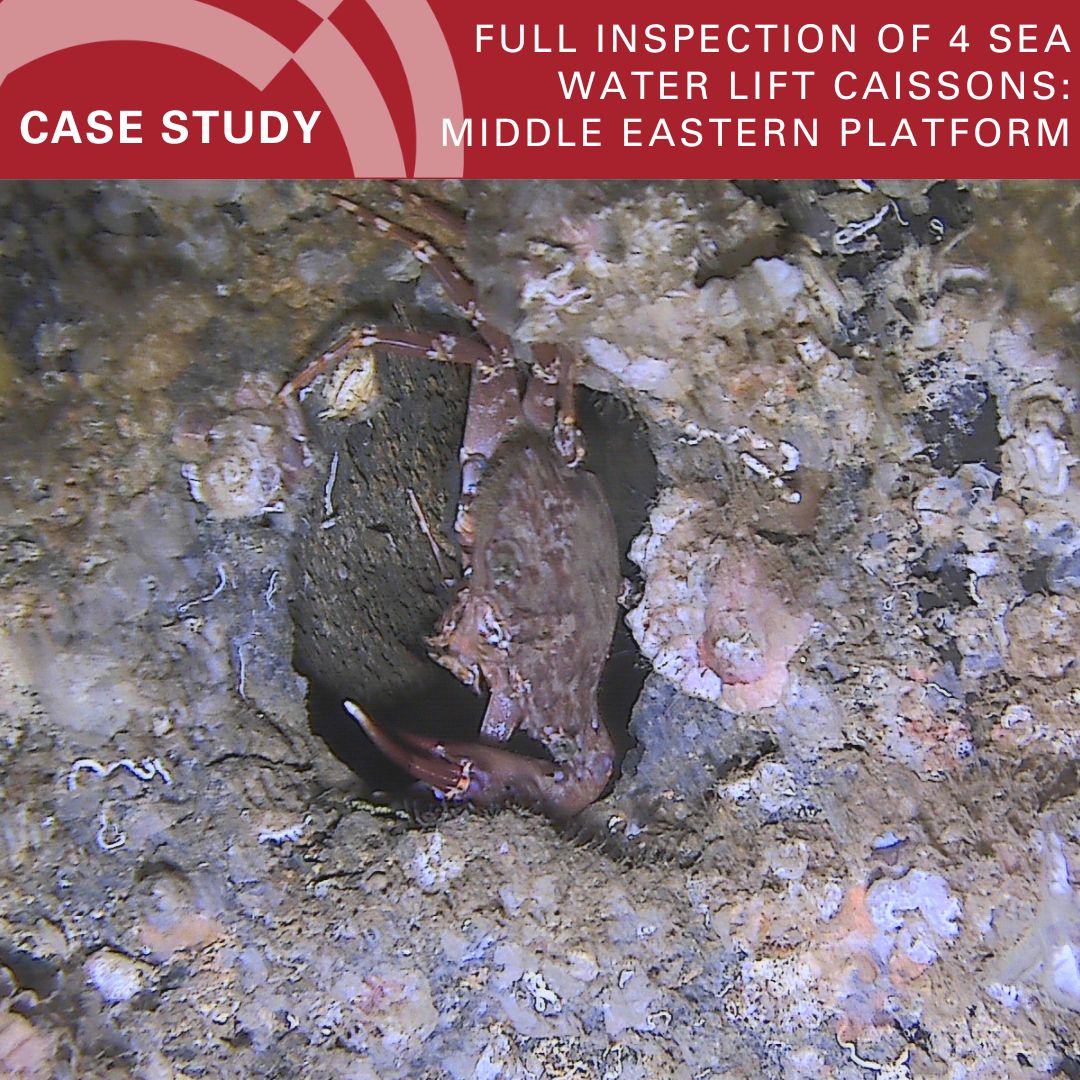

At AISUS, we excel in overcoming complex inspection challenges by delivering tailored solutions that prioritise safety and efficiency. One of our leading tools, Aurgia, was among our earliest developments. Equipped with visual subsea cameras, laser scans, ultrasonic testing (UT), and high-pressure cleaning capabilities, Aurgia has been integral to inspecting caissons and other critical infrastructure. Recently, our expert design and engineering team advanced this tool’s functionality by integrating a robotic arm, enabling it to access confined spaces and hard-to-reach areas both offshore and onshore.

Requirements

Inspection of caissons and subsea structures often involves hard-to-reach areas, such as under guide frames or where structural components meet. These confined spaces pose significant challenges to personnel, including increased risk, operational complexity, and higher costs. AISUS’ remote inspection solutions are not only safer but also more cost-effective.

Traditionally, external crawlers could struggle to maintain contact with the structure while inspecting awkward angles or confined areas, requiring disengagement of the technology and structure. To address this, AISUS introduced a robotic arm to Aurgia, enabling seamless access to these problematic zones, eliminating the need for tool to be repositioned around the guide frame.

The Results

The integration of robotics with the Aurgia tool has set new standards in inspection efficiency. With our advanced capabilities, we have successfully completed inspections in some of the industry’s most challenging environments, providing clients with detailed data management while maintaining safety and reducing costs.

This innovation highlights our commitment to pushing the boundaries of remote inspection technology, ensuring we remain a leader in delivering optimal solutions for complex industrial challenges.

Benefits

- Precision in Challenging Areas: Robotics allow for additional reach under guide frames and into confined spaces with accuracy.

- Single Deployment: The system combines cleaning, inspection, and NDT into one streamlined operation.

- Cost-Effective: By minimising personnel and reducing the need for additional vendors costs are effective.

- Increased Safety: Fully remote operation eliminates the need for divers and ROVs in hazardous environments.

- Tailored Solutions: From design concept to manufacturing.