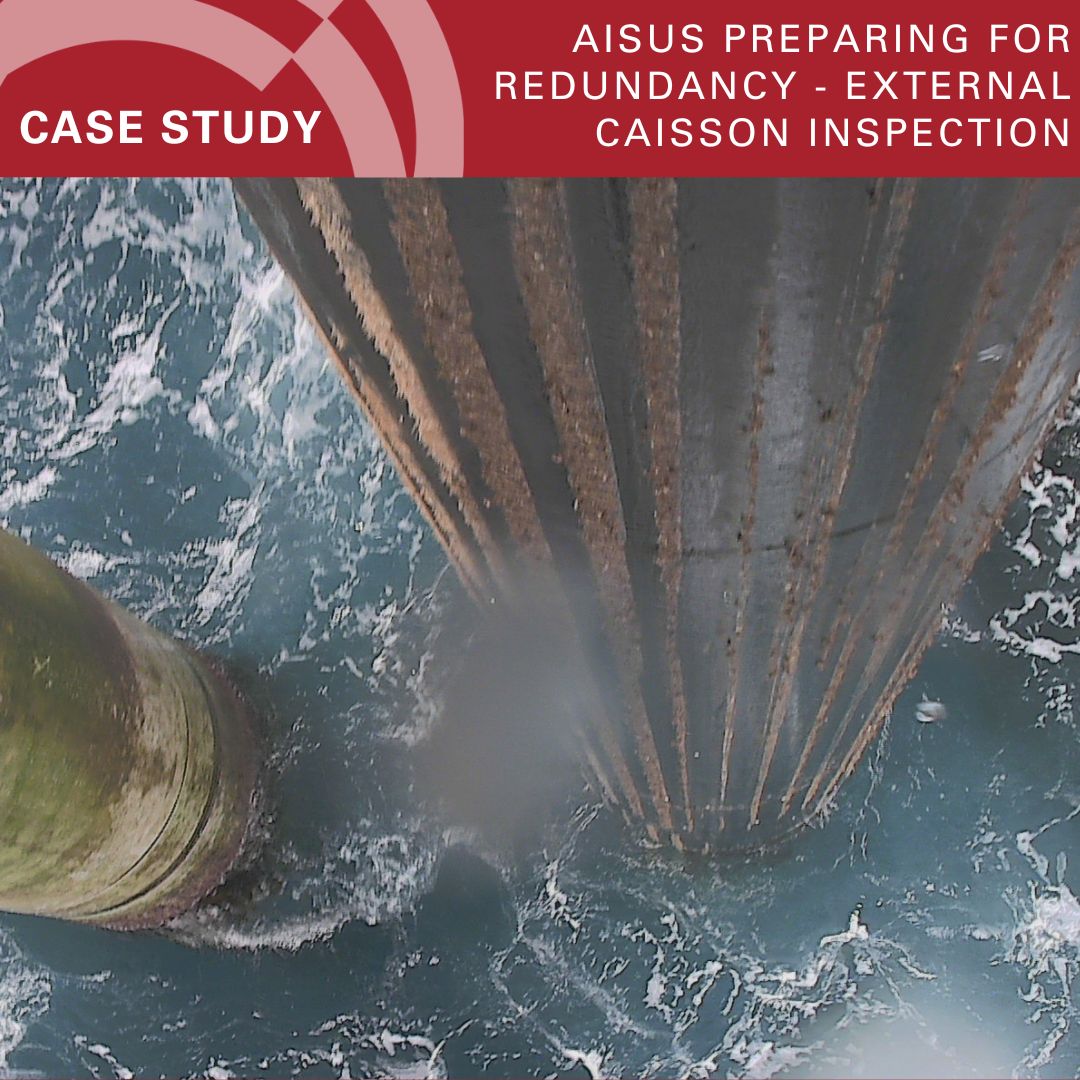

Project Overview

AISUS were approached by a current client of ours to provide Remote Visual Inspections (RVI) and Fluid Sampling in various carrier caissons.

Requirement

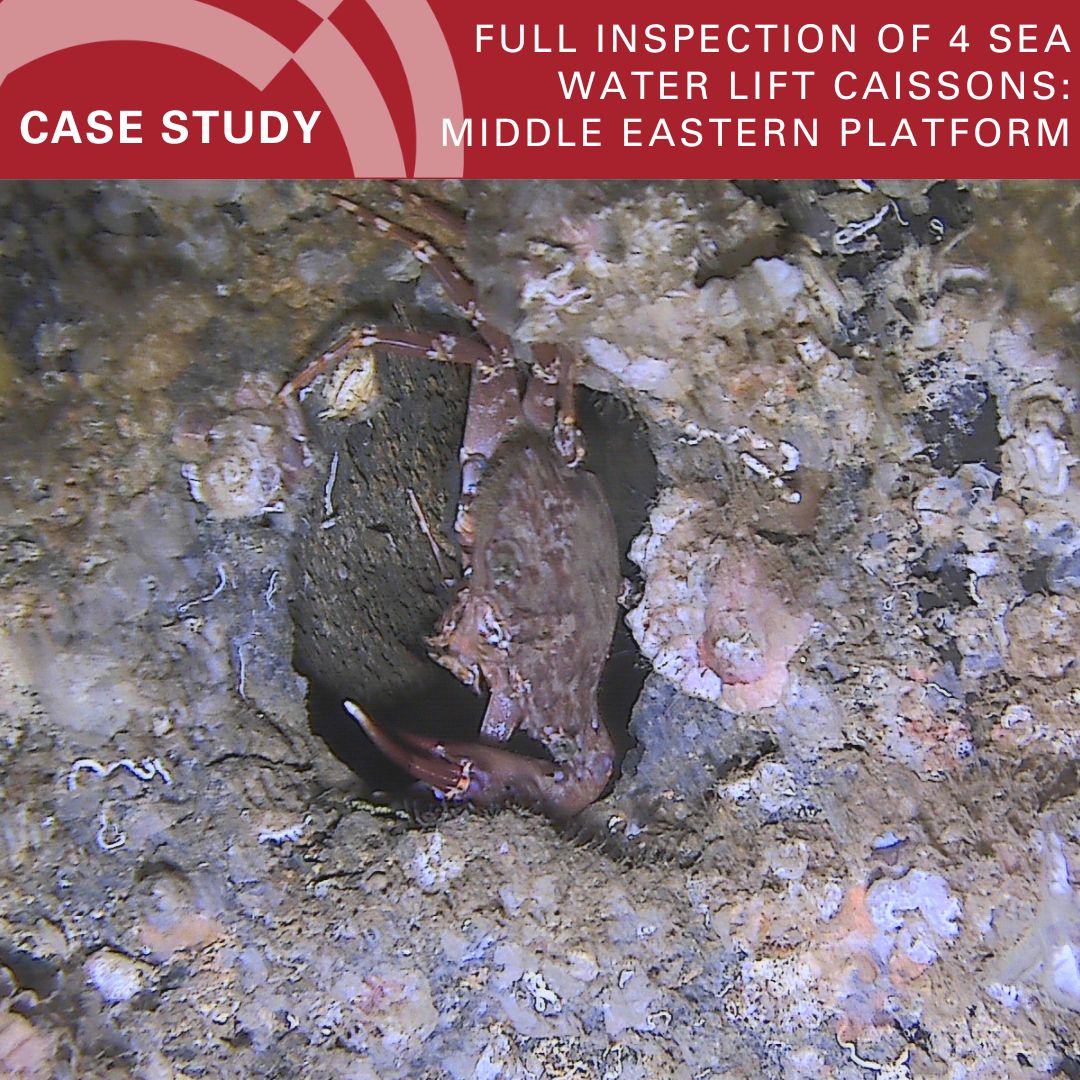

The requirement of the Remote Visual Inspection was to assess internal integrity, record any anomalies found and to acknowledge the presence of corrosion inhibiters/gels.

Provide a sampling tool that could take samples at the correct depths and prevent cross contamination. Once the samples are taken the fluid samples are to be returned onshore for

detailed analysis, either arranged by the client or managed by AISUS through our preferred supplier of oilfield microbiology services.

Challenges

The challenges for the remote visual inspection were access into the carrier caissons, internal obstacles/supports and visibility within the fluid.

For the fluid sampling the challenges again was the obstacles/supports and gathering the fluid sample at the correct depths without cross contamination.

Approach

The challenges was resolved by identifying suitable and accessible entry points which would maximise the manoeuvrability for both the remote visual inspection and fluid sampling.

AISUS designed a unique sampling tool which allowed samples to be taken at the designated depths and with an accompanied and comprehensive operational procedure, this ensured there was negligible sample contamination.

Results

The inspection and fluid sampling was a success with video and digital stills captured revealing corrosion inhibiter / gel. Numerous fluid samples of the designated depths was also recovered and sent onshore for analysis. AISUS received very positive feedback as it was completed within the clients’ timeframe and was executed in a professional manner

Benefits

AISUS can provide temporary or permanently installed systems for collecting fluid samples from within varying pipework. This application can be utilised in commissioning, operations, maintenance and decommissioning projects.

Where required AISUS combine visual inspection with sampling, which is particularly effective for the inspection of Hydrocarbon Riser (Carrier) Caissons.

This combined service provides the required information to determine a suitable and sufficient integrity management strategy for such riser systems