Overview

AISUS has revolutionised the industry with our innovative data management platform. Through integrating artificial intelligence (AI) and machine learning (ML) capabilities we provide our clients with unparalleled insights into their assets. AISUS’ computer software transformed traditional data management reports for our client, enabling them to achieve greater control, optimised operational efficiency and make accurate decisions through the real-time data visualisation at their fingertips.

Requirement

A leading offshore client approached AISUS with an inspection challenge, requiring data reports of their ageing offshore platform which was experiencing corrosion-related issues. The client required immediate data with accurate defect detection to minimise operational downtime and costly repairs.

Solution

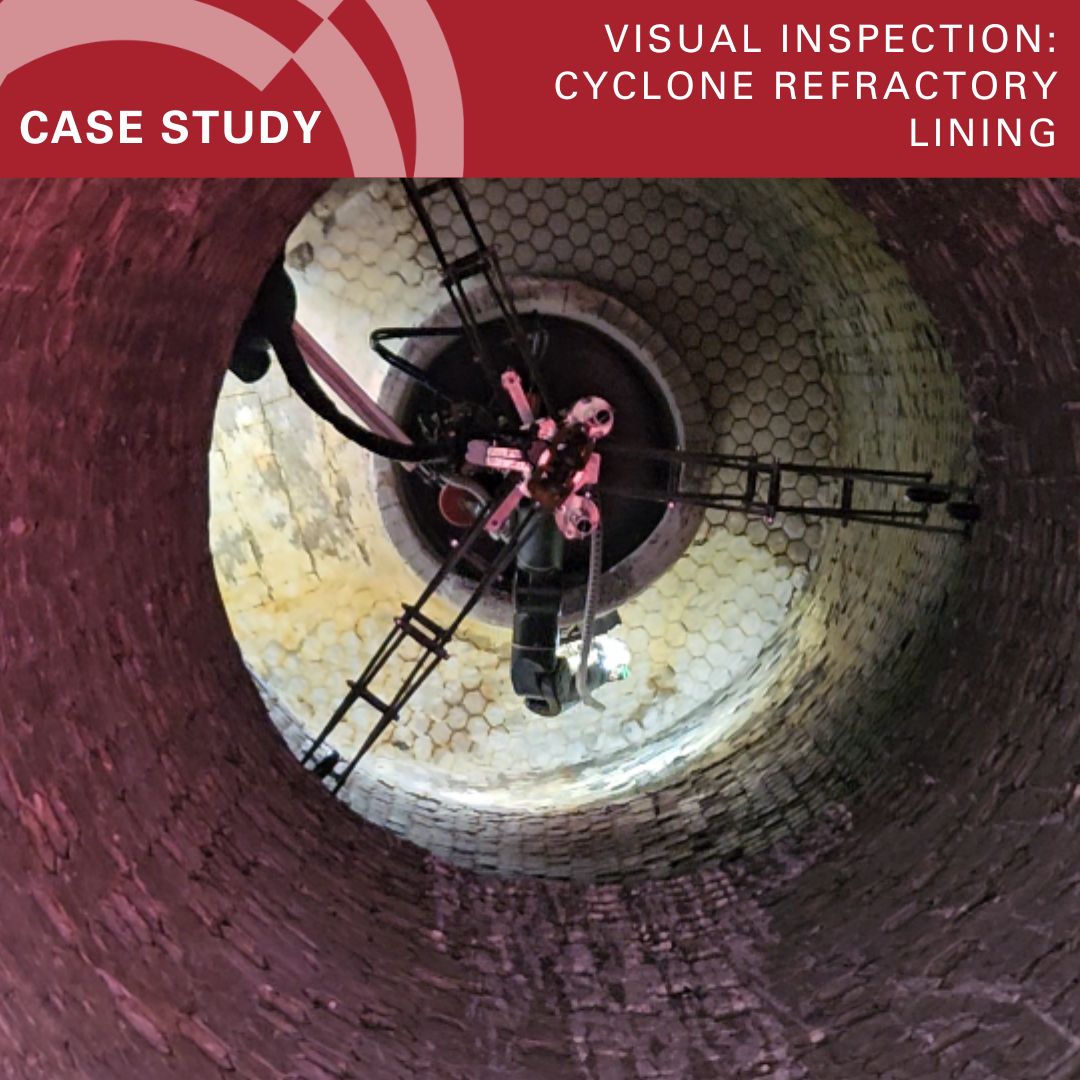

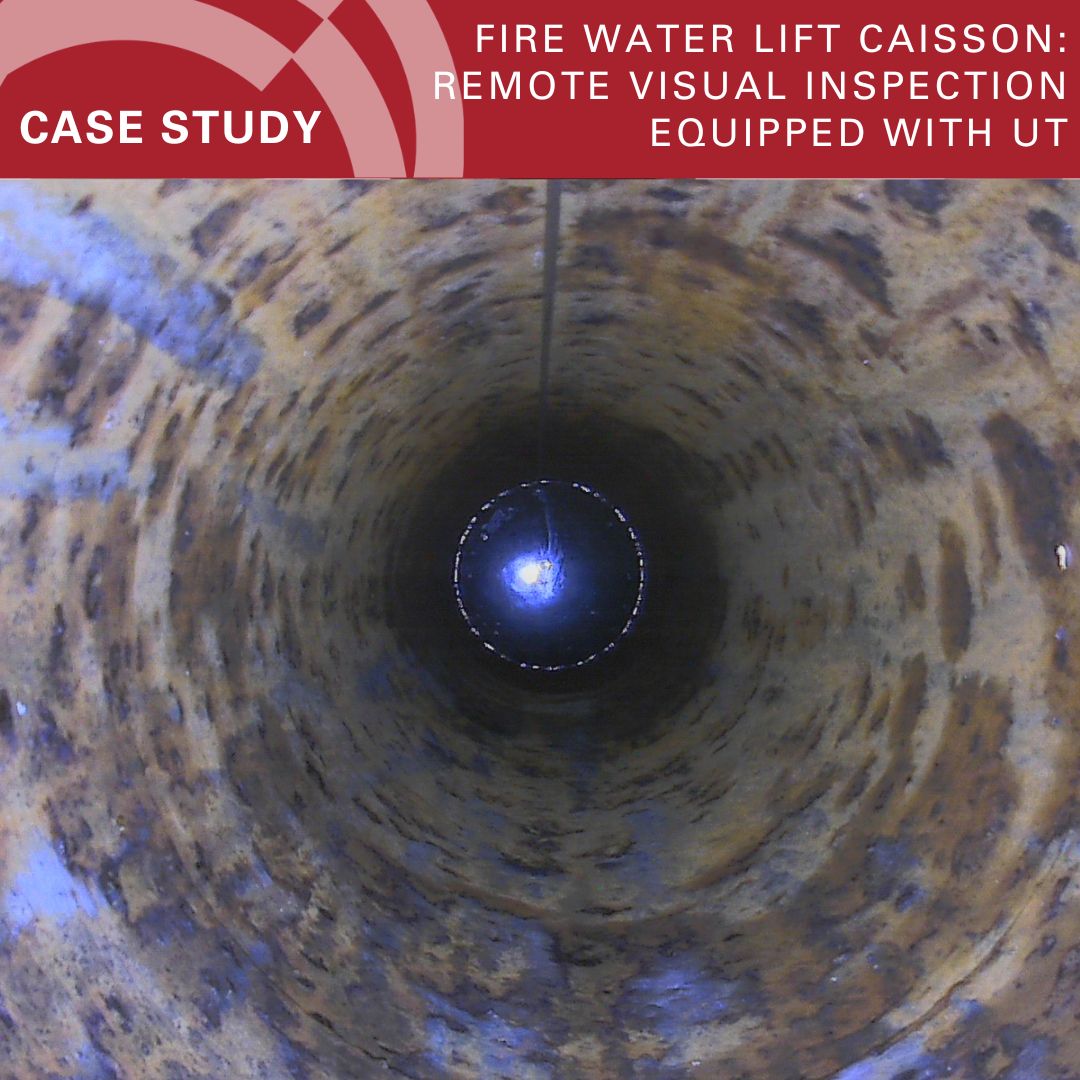

AISUS deployed an internal tool equipped with a HD camera to gather visual inspection data across the client’s offshore platform. Leveraging AISUS’ data management platform, the collected data was immediately processed using our advanced computer vision software and expert team of data scientists.

Our computer software generated detailed 3D photogrammetry models of the client’s assets, created from the digital point cloud datasets. The data models were then animated for a virtual reality experience, which allowed the client to step inside their assets and visualise the defeats first hand.

The client was able to login into our seamless data management platform at their convenience. The user-friendly platform allowed our client to interact with their data through the immersive virtual reality experience, making it easier to understand the asset’s condition and make timely decisions. Our platform eliminated the need for traditional static reporting which would have been overwhelming for the client.

Results

Comprehensive Data: Our computer software and data scientists stitched the high-resolution visual inspection images together, which created various visualisation formats for the client to explore their assets. Offering panoramas, 3D photogrammetry models and accurate labelled defect sizing from AI capabilities.

Advanced Anomaly Detection: The real-time visual data was then fed into AISUS’ machine learning algorithms, to classify anomalies and defects within the offshore structure. The algorithm detected potential issues such as corrosion, cracks and welding weaknesses. This capability enabled AISUS to identify defects at an early stage in the most time-effective way.

Data Fusion: The data management platform provided the client with data from multiple sources, including the splashzone, internal structures and subsea areas of the platform. The ability to view the full asset in a single, integrated view was instrumental in aiding the client’s decision-making process, as it highlighted areas of concern and allowed for strategic planning.

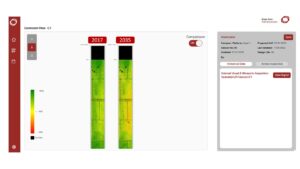

Predictive Corrosion: AISUS’ AI-driven data management platform analysed historical inspection data, alongside the real-time data gathered during this visual inspection on the client’s platform, to generate predictive maintenance. By evaluating the deterioration rate from the AI prediction, this insight was highly appreciated by the client as an additional feature to aid with scheduling proactive maintenance.

Benefits

Enhanced operation efficiency: real-time data visualisation and immediate defect detection streamlines the inspection process, reducing time required assessing the asset’s condition.

Proactive maintenance: predictive maintenance capabilities lead to reduction in unplanned downtime, minimising costly repairs and extending the lifespan of assets.

Decision-making: The comprehensive data management platform allows the client to make strategic decisions with confidence.

Increased safety: early anomaly detection prevents potential safety hazards, ensuring the continued integrity of offshore platforms.