Overview

Inspecting assets often involves navigating unique aspects and hard-to-reach areas, presenting significant challenges. AISUS’ specialised design and engineering team addresses these challenges head-on, creating custom solutions that exceed client expectations. For this unique project, AISUS provided the most efficient and cost-effective solution tailored to the client’s specific requirements.

Requirement

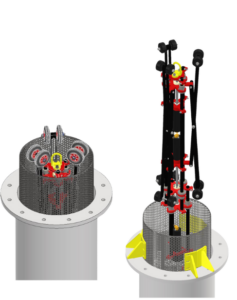

The client required ultrasonic testing (UT) integrity inspection and oval measurement of the lower section of each of an FPSO’s four I-Tubes; specifically in the area of the table chain. The challenge was a 3.5 metre gap between the upper and the lower sides of the I-Tube and chaintable, which required stabilising the internal inspection tool difficult especially subsea.

Approach

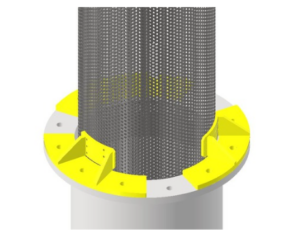

AISUS’ in-house design and engineering team developed a custom sleeve to bridge the gap between the lower and upper sections of the I-Tube to the chaintable. Once deployed, this sleeve enabled the internal inspection tool to pass through safely and effectively. A high-pressure jetting cleaner was mobilised to remove unwanted debris prior to the UT inspection, ensuring optimal results. The UT inspection then determined the wall thickness and ovality of the four I-Tubes. Problem Solving: AISUS utilised our in-house team from initial design concept to manufacturing the necessary tools, completing the full project independently with custom solutions. This approach enabled AISUS to undertake the previously impossible inspection, providing the client with comprehensive data, including imagery available on our data management platform.

Challenges

The significant challenge for AISUS was to deign and manufacture a sleeve which acted a a bridge between the upper and lower side of the I-Tube, eliminating the 3.5m gap which made inspection otherwise impossible.

Meticulous Design: AISUS’ in-house team designed the sleeve to slot perfectly into the I-Tube and chainable while holding the wheeled inspection tool securely inside.

Mobilisation: The sleeve was produced from perforated stainless steel and built in 1 metre sections to address access limitations. 6 components were assembled on-site, ensuring efficient and incident-free deployment.

Flexible Approach: Further challenges included a problematic gauge pipe, additional client requirements and the need for client approval of all design drawings. AISUS demonstrated agility and flexibility in addressing these issues.

Results

AISUS’ unique solution minimised downtime and eliminated the need for ROV and additional support. The work scope was completed on time and within budget, with AISUS performing additional cleaning ahead of schedule, creating cost efficiencies for the client.

Custom Solution Benefits

Tailored Services: from design to manufacture, our solution align perfectly with specific needs, ensuring accuracy and efficiency at every step.

All Under One Roof: Our streamline process minimises time, from initial consultation to final reporting.

Cost-Effective: By integrating necessary tools within a single project, we eliminate unnecessary expenses associated with multiple vendors.

Expert Team and Innovative Technology: We pride ourselves on delivering precise and reliable results, offering personalised support to maintain the highest standards of quality and safety.