Renewable Energy Sector

At AISUS we are supporting different energy sectors both onshore and offshore, with our tools versatile for cross industry application. With continued investment in our technology and an expert team of engineers behind us we continue to make strides within the renewable energy sector.

Expanding on this we have recently joined the Fit 4 Offshore Renewable programme, which will allow us to collaborate with industry leaders, innovators, and experts to explore new avenues for growth and innovation. We are excited to engage in this forward-thinking program, enabling us to strengthen our strategic initiatives, enhance our capabilities, and continue to push the boundaries as industry leaders in remote inspection technology.

Case Study: Offshore Wind Farm Weld Remediation

Overview

For over a decade, AISUS has been refining its expertise within the global energy sector. Throughout this period, the energy landscape has undergone significant evolution, driven by the shift towards a carbon-neutral future. Despite these changes, we remain market-leaders in specialist inspection technology, delivering high-standards across all energy sectors.

The Situation

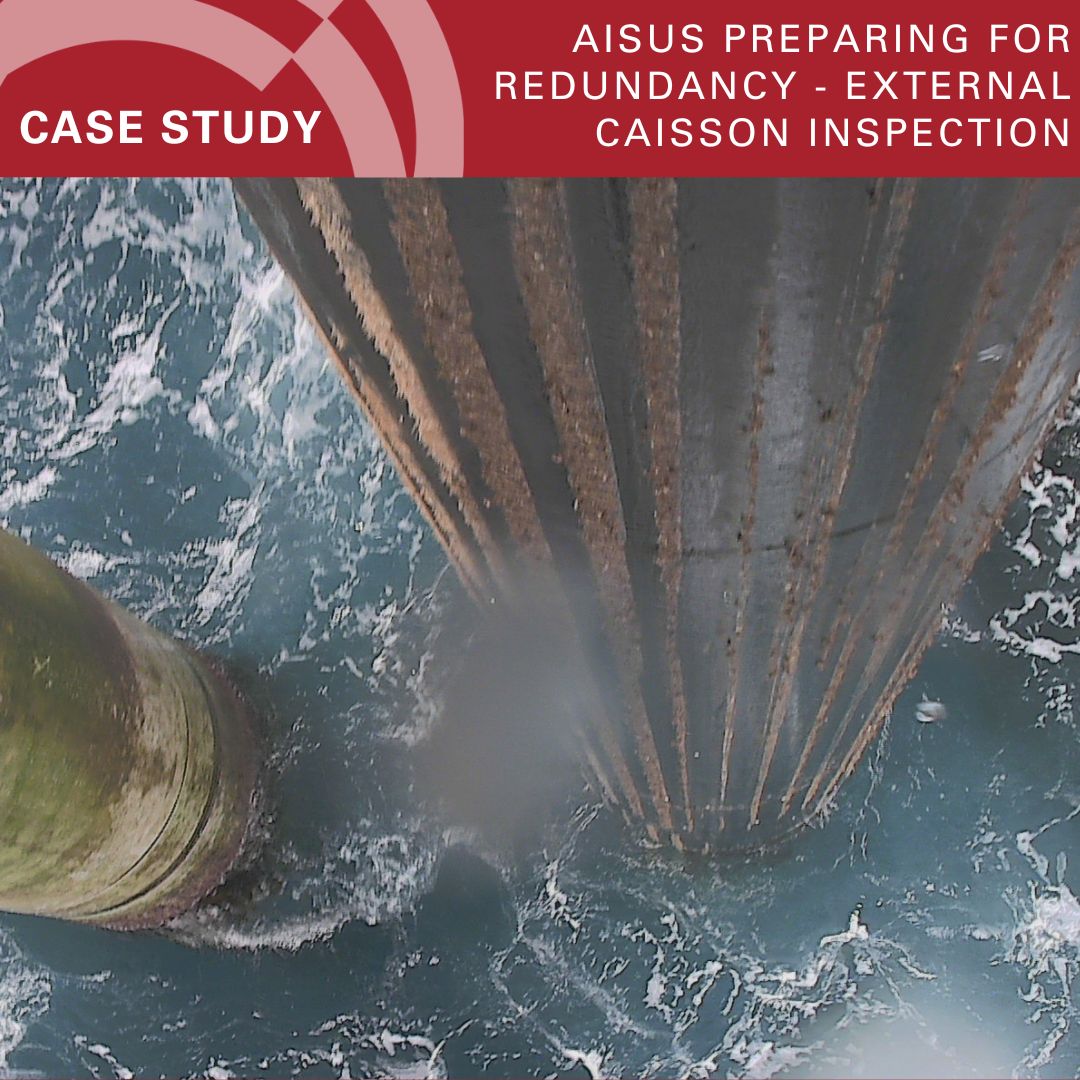

Our client, a wind farm operator, approached us addressing concerns around inconsistent quality of welding performed during the production of the J-Tubes, situated offshore Northern France. They expressed concerns regarding sharp internal metallic edges and protrusions within welded areas, posing a potential threat to any inserted umbilical cables. Prior to cable installation, AISUS conducted inspections on 46 J-Tubes across 26 jackets, totalling to 414 welds. Our findings confirmed the need for remedial welding activities.

The Scope

The two-phased work scope comprised:

- A visual inspection, via general camera, prior to weld scans to ensure that no major equipment had produced an internal blockage. This also identified any internal anomalies with the potential to damage inspection equipment or compromise the inspection.

- Laser Scanning to obtain the data of the welds.

- Following inspection of each weld and collation of data for every jacket, our onshore reporting analysis created 360 panoramic, detailed images.

To obtain a flat 360 panoramic view for each weld, all images were collated in mosaic format.

We provided an analysis of the location of any protrusion bigger than 2mm on any weld, advising of the location within the J-Tube from the datum point.

Challenges

Harsh Environments

Taking place in mid-winter, the client anticipated a 50% weather-related downtime. Leveraging AISUS’ 10+ years of experience in harsh offshore environments, we were prepared to operate on a 24-hour shift basis to uphold the client’s schedule.

Visibility Poor

Visibility conditions within the J-Tubes were addressed by flushing them with fresh water to mitigate potential issues.

Logistics

Due to delays, AISUS’ inspection equipment was transported via a Crew Transfer Vessel (CTV) instead of the originally planned Service Operations Vessel (SOV), which would have facilitated the easier transfer of bulky items. To ensure that the scope remained unaffected, we disassembled our equipment into smaller items that could be transferred in bags suitable for the decreased capacity of a CTV.

Increased Work Scope

During the project, an additional scope of work required AISUS to remediate the welds before conducting subsequent laser inspections, providing ‘before and after’ results.

The AISUS Approach

AISUS Problem Solving

The grinding tool employed for this task wasn’t initially intended for marine applications. However, our team of technical experts devised a solution, enabling its effective use offshore.

Continuous Focus

Our mobilisation strategy demanded substantial manpower for an uninterrupted duration of five months. Operating in four rotating teams, each consisting of eight specialists, including four technicians for milling and four for laser inspection.

Results

- Project completed on time and within budget

- The data provided enable our client to make informed decisions on its tie back schedule, whilst ensuring the integrity of cable tie backs.

- After the successful completion of the offshore scope, AISUS was asked to complete additional work on the remaining jackets.

- Following this, the client awarded AISUS a new contact, in a different location.

Contact us: https://www.aisus.co.uk/contact/