Overview

A client required AISUS to inspect a large tunnel under a river for the third time to collect additional data for predictive maintenance and safety assessments. The first inspection involved remote visual inspection and laser scanning, while the most recent inspection required enhanced data collection using AISUS’ 360-degree camera along the full 500m tunnel length.

The Requirement

A three-person team was deployed to execute the inspection, with the aim of the 360 camera system to detect and record:

- General condition of the tunnel and internal pipework

- Corrosion or oxide build-up

- Fallen debris or foreign objects

- Distortion, cracks, or leaks

- Damage or corrosion of visible pipe brackets

The Challenge

- No physical access to the tunnel was permitted, requiring a retrieval rope attached to the crawler in case of power loss.

- Careful handling was necessary when accessing and exiting tunnel entrances.

- Operational delays were possible due to weather conditions.

- The internal pipework obstructed most of the tunnel wall, allowing only a small visible section near the top of the tunnel for measurement and inspection.

The Solution

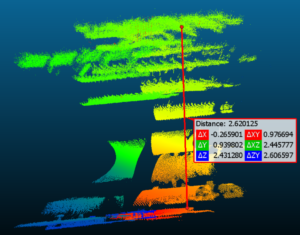

The first inspection was conducted using a remote crawler equipped with a laser scanner. The crawler was driven along the tunnel, stopping at specified intervals to conduct laser scans. A total of five scans were completed at locations specified by the client. At no point was the team permitted access to the tunnel.

For the latest inspection, AISUS deployed the same remote crawler system this time fitted with our 360-degree camera. The inspection recorded high-resolution video footage, capturing:

- General tunnel conditions

- Internal pipework anomalies

- Foreign objects or debris

The recorded footage was reviewed, edited, and annotated by AISUS’ engineers and data team, ensuring comprehensive analysis and reporting. The client’s decision to proceed with a third inspection followed the success of the initial data collection. AISUS was able to integrate findings from previous inspections, enabling a comparative analysis and a more detailed understanding of asset conditions over time.

AISUS’ advanced inspection solutions provided the client with high-quality, multi-format data, enabling informed decision-making for tunnel maintenance and safety. The continued collaboration highlights AISUS’ commitment to delivering cutting-edge remote inspection technology that enhances asset integrity management.

Benefits

- Reduced Personnel Needs: A small three-person team was required, minimising risk and optimising efficiency.

- Cost-Effective: AISUS’ consolidated solution eliminated the need for multiple vendors, reducing overall inspection costs.

- Accurate Data Collection: The combination of laser scanning, 360-degree imaging, and video visual inspection provided a thorough and reliable dataset, including 3D models and detailed visual records.